Qaybaha Semiconductors Elektaroonigga ah TPS7A5201QRGRRQ1 Ic Chips adeega BOM Hal goob iibso

Sifooyinka Alaabta

| NOOCA | SHARAXA |

| Qaybta | Wareegyada isku dhafan (ICs) |

| Mfr | Qalabka Texas |

| Taxane | Gawaarida, AEC-Q100 |

| Xidhmada | Cajalad & Gariir (TR) Jaran Cajalad (CT) Digi-Reel® |

| SPQ | 3000T&R |

| Xaaladda Alaabta | Firfircoon |

| Habaynta wax soo saarka | Wanagsan |

| Nooca wax soo saarka | la hagaajin karo |

| Tirada Nidaamiyeyaasha | 1 |

| Voltage - Gelida (Max) | 6.5V |

| Voltage - Soo-saarka | 0.8V |

| Voltage - Wax soo saarka (Max) | 5.2V |

| Korontada ka bixida (Max) | 0.3V @ 2A |

| Hadda - Wax-soo-saarka | 2A |

| PSRR | 42dB ~ 25dB (10kHz ~ 500kHz) |

| Tilmaamaha Xakamaynta | Daar |

| Astaamaha Ilaalinta | Heerkulka ka badan, Celceliska Cirifka |

| Heerkulka shaqada | -40°C ~ 150°C (TJ) |

| Nooca Koritaanka | Dusha sare |

| Xidhmada / Kiis | 20-VFQFN suuf qaawan |

| Xidhmada Aaladda Bixiyaha | 20-VQFN (3.5x3.5) |

| Lambarka Alaabta Saldhigga | TPS7A5201 |

Dulmarka chips

(i) Waa maxay chip

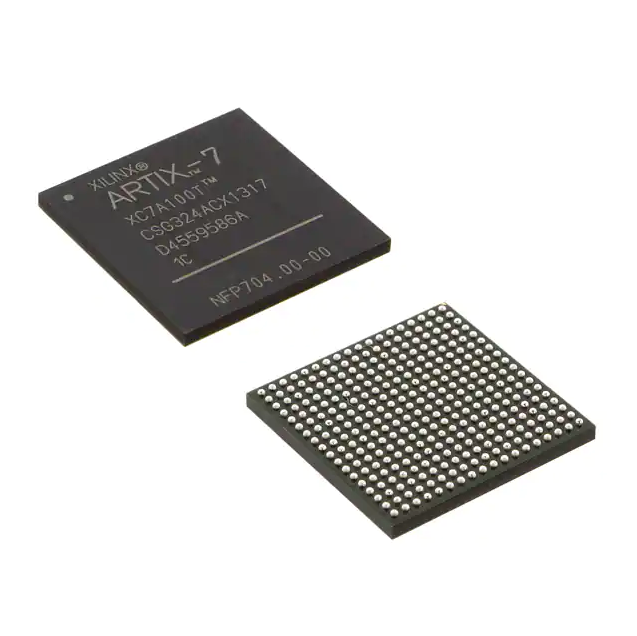

Wareegga isku dhafan, oo loo soo gaabiyo IC;ama microcircuit, microchip, chip-ku waa hab lagu yareeyo wareegyada (inta badan qalabka semiconductor, laakiin sidoo kale qaybaha dadban, iwm.) ee elektiroonigga ah, waxaana badanaa lagu soo saaraa dusha sare ee waferrada semiconductor.

(ii) Habka wax soo saarka Chip

Habka wax-soo-saarka chip-ka oo dhamaystiran waxa ka mid ah nakhshad jajabka, samaynta wafer-ka, samaynta baakadaha, iyo tijaabinta, kuwaas oo habka wax-soo-saarka wafer uu si gaar ah u adag yahay.

Marka hore waa naqshadeynta chip-ka, marka loo eego shuruudaha naqshadeynta, "qaabka" la soo saaray, alaabta ceeriin ee jajabku waa wafer.

Waferku waxa uu ka samaysan yahay silikoon, kaas oo laga sifeeyay ciid quartz ah.Waferku waa curiyaha silikoon ee la nadiifiyay (99.999%), ka dibna silikoon saafi ah ayaa laga sameeyaa ulo silikoon, kaas oo noqda walxaha wax soo saarka quartz semiconductors ee wareegyada isku dhafan, kuwaas oo loo jarjaray wafers wax soo saarka chip.Khafiifka wafer-ka, ayaa hoos u dhigaya qiimaha wax-soo-saarka, laakiin inta badan habka loo baahan yahay.

dahaarka wafer

Dahaarka Waferku wuxuu u adkaystaa oksaydhka iyo iska caabinta heerkulka waana nooc ka mid ah sawir-qaadista.

Wafer photolithography horumarinta iyo xoqidda

Socodka aasaasiga ah ee habka sawir-qaadista ayaa lagu muujiyay jaantuska hoose.Marka hore, lakabka sawir-qaadista ayaa lagu dabaqaa dusha sare ee waferka (ama substrate) oo la qalajiyo.Ka dib marka la qalajiyo, waferka waxaa loo wareejiyaa mashiinka lithography.Iftiinka ayaa la dhex maraa maaskaro si loo mariyo qaabka maaskarada dusha sare ee sawir-qaadista ee dusha sare ee wafer, taasoo awood u siinaysa soo-gaadhista iyo kicinta falcelinta sawir-kiimeedka.Wafersyada qaawan ayaa markaa la dubaa mar labaad, oo loo yaqaan dubitaanka soo-gaadhista ka dib, halkaas oo fal-celinta photochemical ay aad u dhammaystiran tahay.Ugu dambeyntii, horumariyaha ayaa lagu buufiyaa sawir-qaadaha dusha sare ee wafer si loo horumariyo qaabka bannaanka ah.Horumarinta ka dib, qaabka maaskarada ayaa looga tagay sawir-qaade.

Xabagta, dubista, iyo horumarinta dhamaantood waxaa lagu sameeyaa soosaaraha xoqida iyo soo-gaadhista waxaa lagu sameeyay sawir-qaadista.Sameeyaha xoqida iyo mishiinka lithography ayaa guud ahaan lagu shaqeeyaa si toos ah, iyada oo maraqyada lagu kala wareejiyo qaybaha iyo mishiinka iyada oo la adeegsanayo robot.Nidaamka soo-gaadhista iyo horumarinta oo dhan waa la xiray oo mareegaha si toos ah uma soo bandhigin deegaanka ku xeeran si loo yareeyo saameynta qaybaha waxyeellada leh ee deegaanka ee falcelinta sawir-qaadista iyo sawir-kimeedka.

Doping oo leh wasakh

Ku dhejinta ions ee waferka si loo soo saaro semiconductors nooca P iyo N ee u dhigma.

Tijaabada wafer

Ka dib hababka kor ku xusan, shabag laadhuu ah ayaa lagu sameeyay waferka.Tilmaamaha korantada ee qof kasta oo dhinta waxaa lagu hubiyaa iyadoo la isticmaalayo tijaabada biinka.

Baakadaha

Waferrada la soo saaray waa kuwo go'an, oo ku xidhan biinanka, waxaana loo sameeyaa baakado kala duwan iyadoo loo eegayo shuruudaha, taas oo ah sababta isku midka ah ee chip-ka loo soo duubi karo siyaabo kala duwan.Tusaale ahaan, DIP, QFP, PLCC, QFN, iyo wixii la mid ah.Halkan waxa inta badan lagu go'aamiyaa caadooyinka codsiga ee isticmaalaha, deegaanka codsiga, qaabka suuqa, iyo arrimaha kale ee ka durugsan.

Tijaabinta, baakadaha

Ka dib habka kor ku xusan, wax soo saarka chip waa dhamaystiran.Tallaabadani waa in la tijaabiyo jajabka, ka saar alaabta cilladaysan oo aad xirto.

Xiriirka ka dhexeeya wafers iyo chips

Chip wuxuu ka kooban yahay wax ka badan hal qalab semiconductor.Semiconductors guud ahaan waa diodes, triodes, tuubooyinka saamaynta garoonka, iska caabiyeyaasha yar yar, inductors, capacitors, iyo wixii la mid ah.

Waa isticmaalka habab farsamo si loo beddelo fiirsashada ee electrons lacag la'aanta ah ee nucleus-ka atomiga ceel wareeg ah si loo beddelo sifooyinka jireed ee nucleus-ka si loo soo saaro lacag togan ama taban oo ah kuwa badan (elektarooni) ama dhowr (god) samee semiconductors kala duwan.

Silikoon iyo germanium waxaa inta badan loo adeegsadaa agabka semiconductor-ka, hantidooda iyo agabkoodana si diyaar ah ayaa loo heli karaa tiro aad u badan iyo qiimo jaban si loogu isticmaalo tignoolajiyadan.

Waferka silikon wuxuu ka kooban yahay tiro badan oo ah aaladaha semiconductor.Shaqada semiconductor waa, dabcan, si ay u sameeyaan wareegga sida loo baahan yahay iyo inay ku jiraan wafer silikoon.