Xirmada LM46002AQPWPRQ1 HTSSOP16 isku dhafka wareegga IC chip qaybaha cusub ee qalabka elektiroonigga ah

Sifooyinka Alaabta

| NOOCA | SHARAXA |

| Qaybta | Wareegyada isku dhafan (ICs) |

| Mfr | Qalabka Texas |

| Taxane | Automotive, AEC-Q100, SIMPLE SWITCHER® |

| Xidhmada | Cajalad & Gariir (TR) Jaran Cajalad (CT) Digi-Reel® |

| SPQ | 2000T&R |

| Xaaladda Alaabta | Firfircoon |

| Shaqada | Hoos-u-dhac |

| Habaynta wax soo saarka | Wanagsan |

| Topology | Buck |

| Nooca wax soo saarka | la hagaajin karo |

| Tirada Waxsoosaarka | 1 |

| Voltage - Gelida (min) | 3.5V |

| Voltage - Gelida (Max) | 60V |

| Voltage - Soo-saarka | 1V |

| Voltage - Wax soo saarka (Max) | 28V |

| Hadda - Wax-soo-saarka | 2A |

| Soo noqnoqda - Beddelka | 200kHz ~ 2.2MHz |

| Dib-u-habayn isku xidhan | Haa |

| Heerkulka shaqada | -40°C ~ 125°C (TJ) |

| Nooca Koritaanka | Dusha sare |

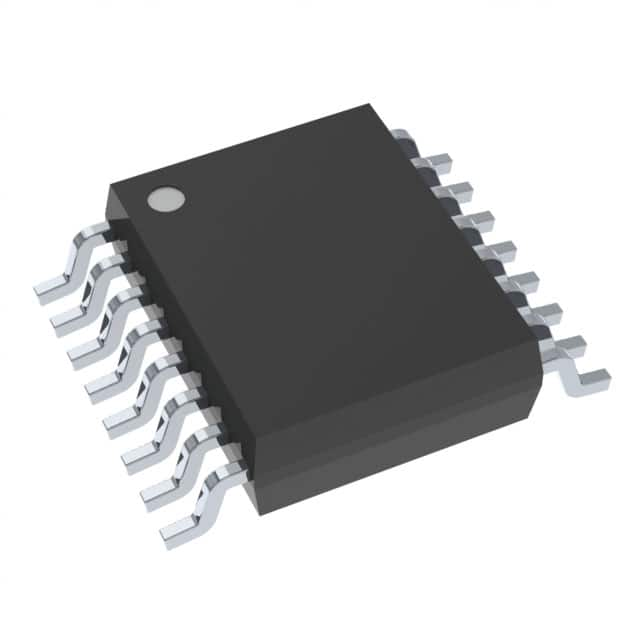

| Xidhmada / Kiis | 16-TSSOP (0.173 ", 4.40mm ballac) suuf qaawan |

| Xidhmada Aaladda Bixiyaha | 16-HTSSOP |

| Lambarka Alaabta Saldhigga | LM46002 |

Habka wax soo saarka Chip

Habka wax-soo-saarka chip-ka oo dhameystiran waxaa ka mid ah naqshadeynta jajabka, wax-soo-saarka wafer, baakadaha jajabka, iyo tijaabinta jajabka, kuwaas oo habka wax-soo-saarka wafer uu si gaar ah u adag yahay.

Tallaabada ugu horreysa waa naqshadeynta chip-ka, taas oo ku saleysan shuruudaha naqshadeynta, sida ujeedooyinka shaqeynta, qeexitaannada, qaabka wareegga, dabaysha fiilada iyo faahfaahinta, iwm. "sawirrada naqshadeynta" ayaa la soo saaray;Sawir-qaadista waxaa horay loo soo saaray iyadoo la raacayo qawaaniinta chip.

②wax soo saarka wafer.

1. Waferrada silikoon ayaa la gooyaa dhumucda loo baahan yahay iyadoo la isticmaalayo maraqa wafer.Khafiifka wafer-ka, ayaa hoos u dhigaya qiimaha wax-soo-saarka, laakiin inta badan habka loo baahan yahay.

2. ku dahaadhi dusha waferka oo leh filim sawir qaade ah, kaas oo hagaajinaya caabbinta wafer ee oksaydhka iyo heerkulka.

3. Kobcinta sawir-qaadista wafer iyo etching waxay isticmaashaa kiimikooyin xasaasi u ah iftiinka UV, ie way jilicsanaanayaan marka ay la kulmaan iftiinka UV.Qaabka chip-ka waxaa lagu heli karaa iyadoo la xakameynayo booska maaskarada.Photoresisist ayaa lagu dabaqaa waferka silikoon si uu u milmo marka uu soo gaadho iftiinka UV.Tan waxa lagu sameeyaa iyada oo la marsado qaybta hore ee maaskarada si qaybta u soo ifbaxda iftiinka UV ay u milmaan oo qaybtan milmay ayaa markaa lagu dhaqi karaa dareere.Qaybtan milmay ayaa markaa lagu dhaqi karaa dareere.Qeybta soo hartay ayaa markaa loo qaabeeyey sida sawir-qaadaha, oo na siinaya lakabka silica ee la rabo.

4. Duritaan ion.Isticmaalka mishiinka etching, N iyo P dabinada waxaa lagu dhejiyaa silikoon qaawan, iyo ions ayaa la isku duraa si ay u sameeyaan isgoysyada PN (albaab macquul ah);lakabka birta sare ayaa markaa ku xiran wareegga iyadoo la adeegsanayo roobabka kiimikada iyo jirka.

5. Tijaabada Waferka Ka dib hababka kor ku xusan, shabag laadhuu ah ayaa lagu sameeyay maraqa.Tilmaamaha korantada ee qof kasta oo dhinta waxaa lagu tijaabiyaa tijaabinta biinanka.

③Baakadaha Chip

Waferka dhammaatay waa mid go'an, oo ku xidhan biinanka, waxaana loo sameeyaa baakado kala duwan iyadoo loo eegayo baahida.Tusaalooyinka: DIP, QFP, PLCC, QFN, iyo wixii la mid ah.Tan waxaa inta badan lagu go'aamiyaa caadooyinka codsiga isticmaalaha, deegaanka codsiga, xaaladda suuqa, iyo arrimaha kale ee ka durugsan.

④Tijaabada Chip

Habka ugu dambeeya ee wax soo saarka chip waa la dhammeeyey imtixaanka alaabta, kaas oo loo qaybin karaa baaritaanka guud iyo baaritaanka gaarka ah, hore waa in la tijaabiyo sifooyinka korantada ee chip ka dib markii baakadaha ee deegaanno kala duwan, sida isticmaalka korontada, xawaaraha hawlgalka, iska caabin danab, iwm. Imtixaanka ka dib, chips-yada waxaa loo kala saaraa darajooyin kala duwan iyadoo loo eegayo sifooyinka korantada.Tijaabada gaarka ah waxay ku salaysan tahay cabbirada farsamada ee baahiyaha gaarka ah ee macmiilka, waxaana la tijaabiyaa qaar ka mid ah chips-yada isku midka ah iyo noocyada kala duwan ee la tijaabiyay si loo eego inay dabooli karaan baahiyaha gaarka ah ee macaamiisha, si loo go'aamiyo in chips gaar ah loogu talagalay macaamiisha.Alaabooyinka ka gudbay imtixaankii guud waxaa lagu calaamadeeyay tilmaamo, nambarada moodeelka, iyo taariikhaha warshadda oo la baakadeeyay ka hor inta aysan ka tagin warshadda.Chips-ka aan gudbin imtixaanka waxaa loo kala saaraa hoos ama la diiday iyadoo ku xiran cabbirrada ay gaareen.

.png)